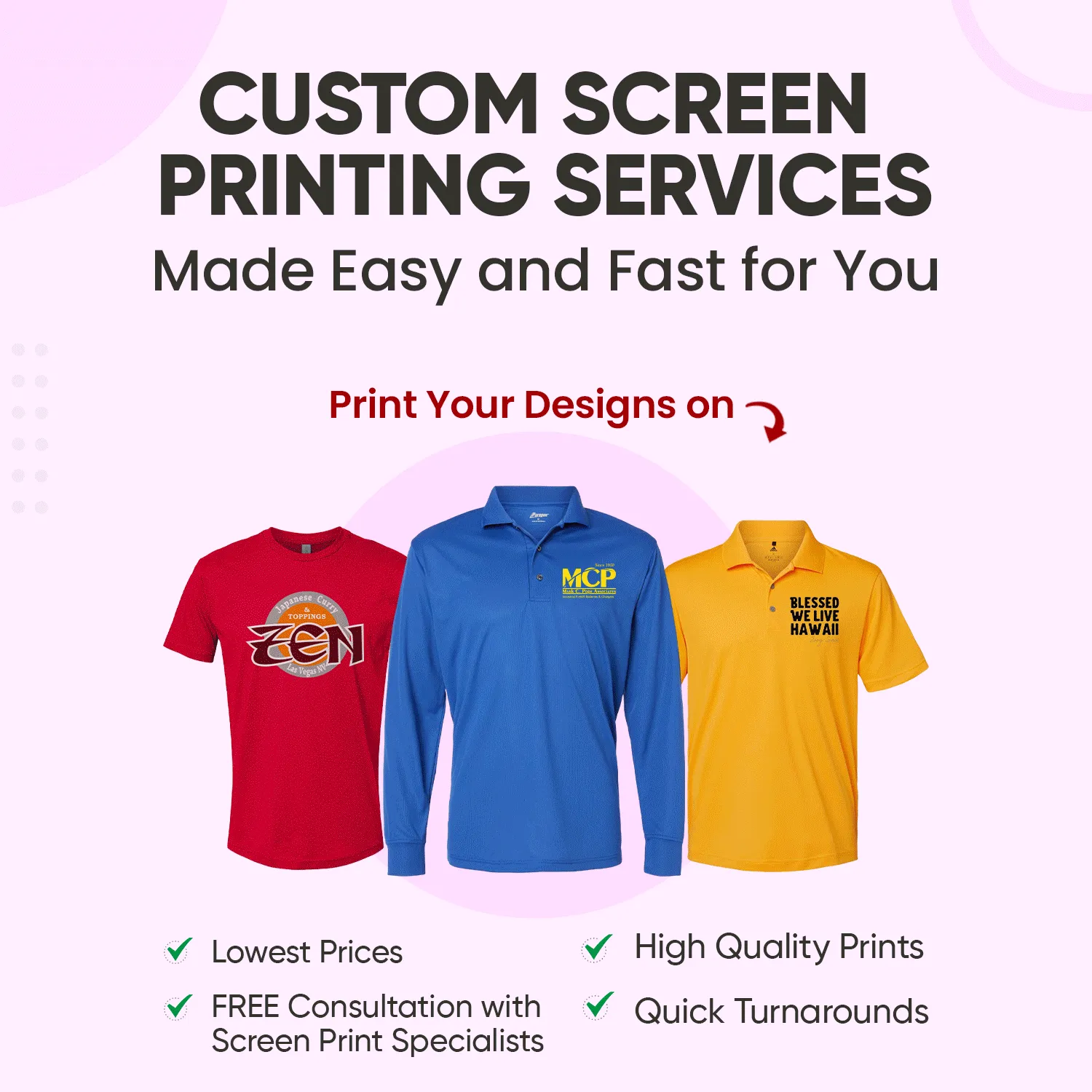

Complete Screen Printing Kit for Artists and Creators

Complete Screen Printing Kit for Artists and Creators

Blog Article

Understanding Silk Screen Printing: Idea for Creating Stunning Designs

If you're looking to master silk screen printing, you'll require more than simply interest. By the end, you'll be ready to create spectacular styles that show your one-of-a-kind design.

Recognizing the Essentials of Silk Display Printing

Silk screen printing, commonly called screen printing, is a functional technique for transferring designs onto various products. You'll discover it's optimal for publishing on textiles, paper, plastic, and extra. The procedure includes creating a stencil, or display, that permits ink to go through just in specific areas, creating dynamic and clean layouts.

To get going, you'll need to prepare your artwork, ensuring it's in an ideal style. screen printing kit. You'll coat your screen with a light-sensitive solution and reveal it to light once you've got your style prepared. This action develops a stencil of your layout on the display

After rinsing the unexposed emulsion, you're readied to publish. Align your display over your product, apply ink, and use a squeegee to push the ink with the display. It's all concerning method and persistence, so do not think twice to experiment and improve your strategy as you go.

Important Tools and Products You'll Need

To begin with silk screen printing, you'll require a couple of standard materials like screens, mops, and ink. When you're comfy, you can check out sophisticated equipment that boosts your printing high quality and efficiency. Allow's discuss what you'll call for to guarantee your projects are effective from the start.

Basic Silk Display Materials

Beginning on a silk display printing job needs a couple of essential tools and materials to ensure your success. You'll require a silk display framework, which holds the mesh that transfers your layout. A squeegee is important for pushing ink through the display onto your substratum. Don't neglect the ink itself; pick colors that suit your design and the material you're publishing on. A light resource is vital for subjecting your screen, together with solution to create your stencil. You'll likewise require a proper office, preferably one that's complimentary and well-lit from dust. Ultimately, stockpile on cleansing products to preserve your devices and keep your displays in excellent problem. With these fundamentals, you're prepared to plunge right into your project!

Advanced Printing Tools

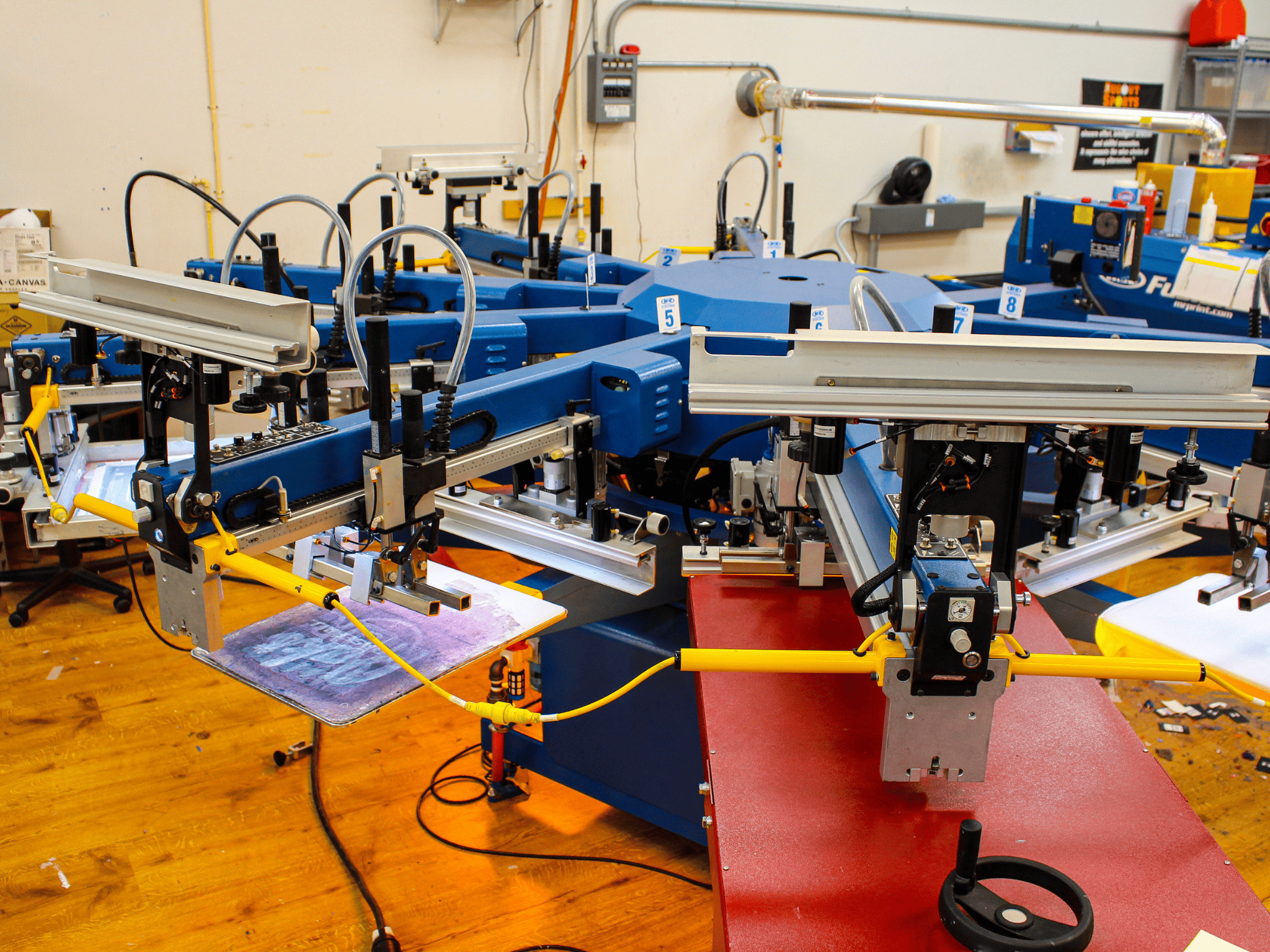

When you prepare to take your silk screen printing to the next degree, buying innovative printing equipment can make a considerable distinction. A high-grade screen printing press is vital; look for a multi-color press that permits specific enrollment and quicker manufacturing. You'll also wish to upgrade to an extra effective exposure unit to ensure your layouts are sharp and vibrant.

Consider purchasing a reliable warm resource, like a conveyor dryer, for also curing of inks. Do not neglect regarding specialized inks; water-based and discharge inks offer excellent outcomes on various textiles. Finally, a good set of mops and emulsion scoop coater will certainly streamline your process, giving your designs that professional edge.

Preparing Your Art Work for Printing

Preparing your artwork for silk display printing is crucial to accomplishing dynamic, specialist results. Start by validating your layout is in the ideal style-- vector documents like.AI or.EPS work best.

Once your documents is all set, develop a different layer for each shade in your style. This'll make it easier during the printing process. Do not forget to include enrollment marks to line up colors appropriately.

Likewise, think about the mesh count of your display; better details may call for a greater mesh matter. Conserve your artwork with a resolution of at least 300 DPI to ensure crisp prints. By following these steps, you'll set on your own up for an effective printing experience and bring your layouts to life perfectly.

The Screen Printing Refine: Step-by-Step

Currently that you have actually prepared your artwork, it's time to focus on the display printing process itself. You'll start by preparing your display, guaranteeing it's all set for the ink application. From there, you'll discover different printing strategies to achieve the finest results for your project.

Preparing Your Screen

Getting your display all set is a critical action in the silk display printing procedure. First, tidy the display thoroughly to get rid of any dust, residue, or grease. Utilize a degreaser and rinse it well to ensure a smooth surface for your emulsion. Next off, use a light coat of emulsion uniformly across the screen using an inside story coater. See to it to do this in a poorly lit location to avoid premature exposure. Allow the solution to dry entirely prior to revealing it to your layout. Once completely dry, position your openness on the screen and use a light source to reveal the layout. After exposure, rinse the unexposed emulsion, and you'll have your screen gotten ready for printing.

Printing Strategies Described

As soon as your screen prepares, you can plunge into the interesting process of printing. Initially, area your display on your substratum-- whether it's material, paper, or another material. Secure it to avoid any kind of movement. Next off, pour your ink onto one side of the display and use a squeegee to pull the ink across the layout. Apply even press to assure the ink penetrates via the mesh. Raise the screen very carefully to disclose your print. Let each layer dry before applying the following if you're layering colors. Tidy your display promptly to prevent ink from drying and clogging the mesh. With method, you'll grasp the subtleties of stress and timing, which will aid you attain crisp, vivid layouts.

Tips for Getting Vibrant Colors

While attaining vibrant colors in silk screen printing might appear tough, you can easily boost your styles with a couple of vital techniques. Pick high-grade inks particularly made for silk screen printing; they provide far better coloring and coverage. Mixing official statement inks appropriately can additionally enhance vibrancy-- experiment with proportions to locate the excellent blend that pops.

Last but not least, don't neglect regarding healing your prints properly. Appropriate heat setting assurances the shades bond with the material, keeping their vibrancy in time. By applying these techniques, you'll develop stunning, appealing designs that absolutely radiate.

Troubleshooting Usual Printing Problems

Despite having dynamic colors in your styles, silk display printing can in some cases provide obstacles. One typical concern is ink bleeding, which usually occurs when you utilize excessive ink or don't let the previous layer completely dry completely. To prevent this, use a squeegee with just the appropriate pressure and assure each layer is dry before including more.

An additional concern is imbalance. If your design isn't lining up correctly, double-check your enrollment marks and make adjustments to your displays. In addition, if you see a lack of information, it could be as a result of a stopped up display. Clean your displays completely before beginning your print run.

Lastly, if the ink isn't sticking well to the material, consider the textile type and the healing process. Make certain you're making use of the ideal ink and that you're healing it at the appropriate temperature. Fixing these common concerns will certainly assist you attain stunning outcomes.

Explore Techniques and Impacts

Exploring with various methods and effects can raise your silk screen printing projects to brand-new elevations. You can additionally play with textures-- making use of different squeegee methods or including products like sponges or brushes includes measurement to your prints.

Take into consideration utilizing specialized inks, such as glow-in-the-dark or metal, to offer your layouts you can find out more an unanticipated twist. You might also discover stenciling, where you can cut intricate styles for stunning impacts.

Do not forget substrate variations! Printing on fabrics, timber, or paper can produce different outcomes that boost your project's feel.

Finally, keep a journal of your experiments. Recording your failures and successes will assist your future creations and assist you refine your style. Welcome the procedure, and delight in the trip of discovering what works best for you!

Often Asked Inquiries

How Do I Tidy and Keep My Screen Printing Tools?

To clean and maintain your display printing tools, on a regular basis scrub screens with an appropriate cleaner, laundry squeegees after usage, and shop everything in a dry, dust-free setting. Maintaining things neat warranties much better prints and longer-lasting tools.

Can I Print on Materials Apart From Textile?

Consider using plastic, paper, or wood. Simply make certain your screens and inks are compatible with those surface areas for the best results.

What Is the very best Means to Shop Screens and Inks?

To save screens and inks efficiently, maintain displays upright in a cool, completely dry area, and cover them to avoid dust. Shop inks in impermeable containers, away from straight sunshine, to preserve their top quality and uniformity.

How Do I Select the Right Mesh Matter for My Task?

Picking the ideal mesh count depends on your style's detail and ink kind. For vibrant styles, a lower count, around 110, works best.

What Are the Environmental Effects of Silk Display Printing?

Silk display printing can have environmental influences, like chemical waste and water use. You can reduce these by utilizing eco-friendly inks, recycling materials, and properly getting rid of chemicals to decrease your project's ecological impact.

Silk screen printing, often called screen printing, is a functional method for moving designs onto various materials. Straighten your display over your product, use ink, and utilize a squeegee to press the ink with the display.To get begun with silk screen printing, you'll require a few basic supplies like screens, squeegees, and ink.When you're ready to take your silk display printing to the next level, you can look here spending in advanced printing devices can make a significant difference.Obtaining your screen prepared is a crucial step in the silk screen printing process.

Report this page